주요메뉴

전체메뉴

COMPANY

PRODUCTS

FACILITY

SUPPORT

FACILITY

HOME

FACILITY

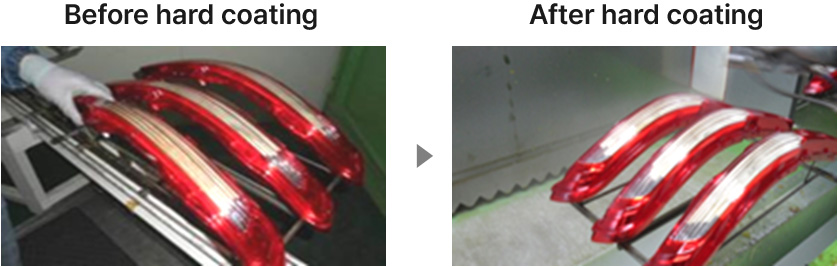

HARD COATING

Hard coating technology that protects the lens with a strong coating and gives it a shiny gloss.

Our company manufactures and supplies types of lamps focusing on hard coating technology that protects lenses of automobile front and rear fog lamps and turn signals from sandy dust generated when driving automobiles through injection molding and vacuum deposition that reflects lights.

Hard coating process

This method is an excellent process that enhances weather resistance and stability by applying a hard coating of UV curable coating to products such as lenses that need to prevent discoloration, Prevention of surface damage, excellent gloss.

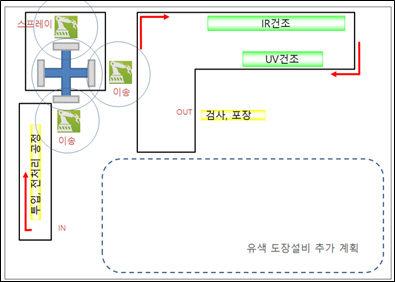

Hard coating first line

| Hard coating first line | |

|---|---|

| Manufacture : 2015/ 10 | I.R dry length : (8M) |

| Producing ability : 1,000EA/HR | U.V dry length : (3M) |

| Spray equip : kawasaki robot | Cooling Zone line : (2M) |

| Conveyor speed : Max. = 2.5M/Min | U.V system : Hg lamp=8 set |

| Pitch : 700mm | U.V amount of light : Max. 5,000 mJ |

| Line length : (78M)/2booth | U.V booth : 2.2M*5.8M*2.15M |

| 1st I.R(Preheat) length : (5M) | Ionizer booth : 1.5M*3.44M*2M |

* Move left and right

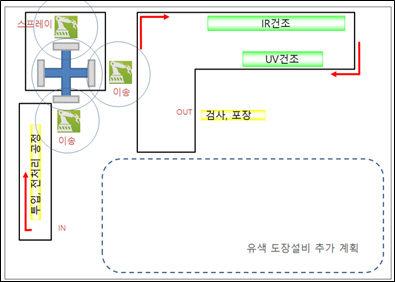

Hard coating second line

| Hard coating second line | |

|---|---|

| Manufacture : 2017/ 11 | I.R dry length : (8M) |

| Producing ability : 1,000EA/HR (Based on 4EA per jig) | U.V dry length : (3M) |

| Spray equip : kawasaki robot | Cooling Zone line : (2M) |

| Conveyor speed : Max. = 2.5M/Min | U.V system : Hg lamp=8 set |

| Pitch : 1,000mm | U.V amount of light : Max. 5,000 mJ |

| Line length : (60M)/1BOOTH | U.V booth : 2.2M*5.8M*2.15M |

| 1st I.R(Preheat) length : (5M) | Ionizer booth : 1.5M*3.44M*2M |

* Move left and right

Hard coating third line

| Hard coating third line |

|---|

| Manufacture : 2022 / 10 |

| Producible size : 1,500mm |

| Producing ability : 430EA / HR (Based on 4EA per jig) 170,000EA / Month (by 20HR/day, 20day/month) |

| Spray facility : YASKAWA articulated robot |

| U.V amount of light : Max. 5,000 mJ |

| Production facility type : booth, input, dry isolation operation, robot transfer method for each section |

* Move left and right